Rotational Moulding, famously known as Roto moulding, is a plastic moulding innovation used in creating hollow objects. A technology unlike other plastic processes, there is no pressure applied here.

Rotational Moulding is used to create a diverse range of products and fit every customer’s needs. It can create any type of mould, regardless of its shapes, sizes, or application. It provides various advantages over conventional plastics processing techniques, such as – a diverse range of products, inexpensive, freedom to work on designs and accuracy.

Piyush Rotomac is an export-oriented company. We have exported our machineries and moulds to numerous countries and Continents including The USA, Europe, Australia, South Africa, Thailand, Libya, Ghana, Bangladesh, Madagascar, Nigeria, Ethiopia, Saudi Arabia, Egypt, etc making us a successful International Exporter.

In the last 30 years, Piyush Rotomac has introduced numerous innovations in the industry – in terms of Designing, Product Innovation, Adopting state-of-art technologies, etc.

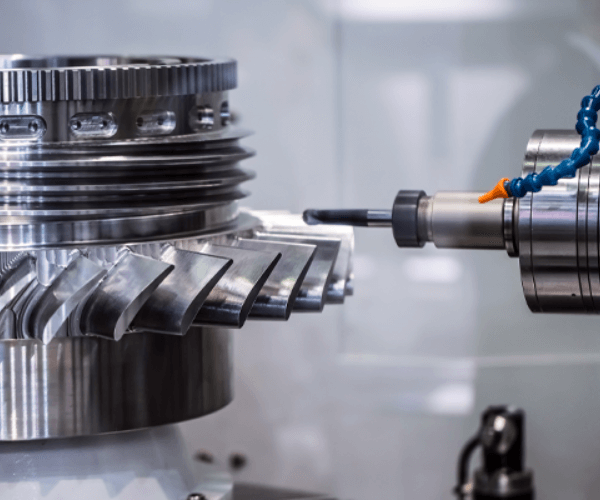

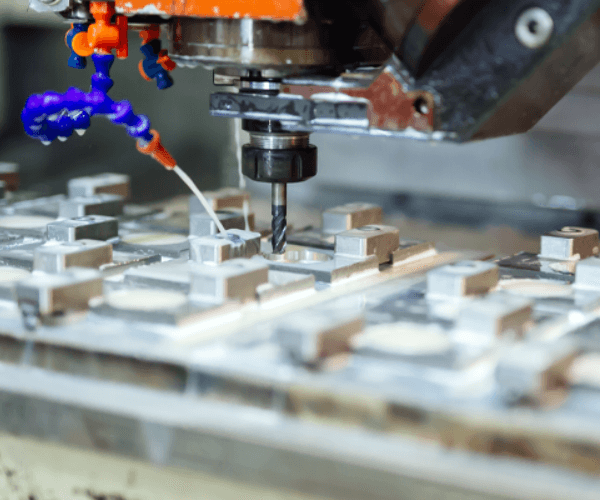

Precision in moulds is difficult but not impossible, however we are achieving it for the last 30 years with consistency. Piyush Rotomac has a unique replenishment model coupled with a robust quality system to achieve the top-notch quality of moulds. We have designed & developed critical moulds as per the customer’s requirement followed by international standards.

We are equipped with the facility of CNC & VMC Machining to achieve its required quality and product satisfaction in final results. Latest technologies, Skilled engineers and dedicated workforce is our ingredient to manufacture superior quality of moulds and Machines.

We have assigned dedicated teams for completing the projects. From Designing team to the Manufacturing team, everyone works in co-ordination with each other.