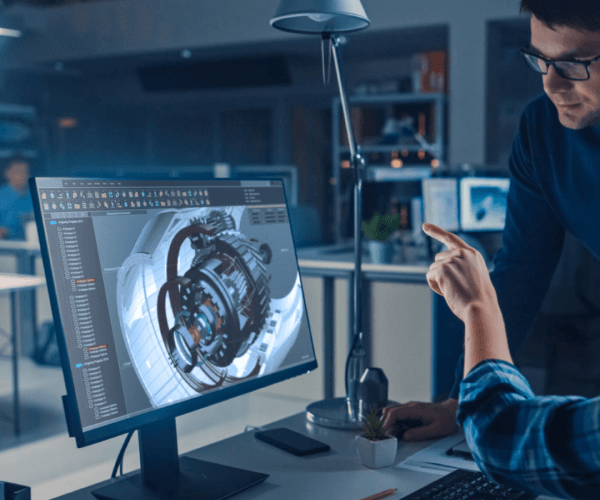

The first and foremost process in Roto moulding is Designing. Our designing team starts with brainstorming the design of moulds, quality and appearance of the products. Understanding the requirements and demands of the customers our experts design the moulds accordingly. If you have your technical design, you can send us and let us know how we should proceed. The design is then sent to customers and get approval from them, the whole project is then transferred to the technical department.

Once the project is received by the technical department, the project head instantly decides the process of manufacturing as per the design. The manufacturing of moulds is done by well-trained engineers, skilled labours and the best resources to produce excellent quality moulds. We are capable to produce the moulds in SS and MS applying CNC ad VMC machining wherever required.

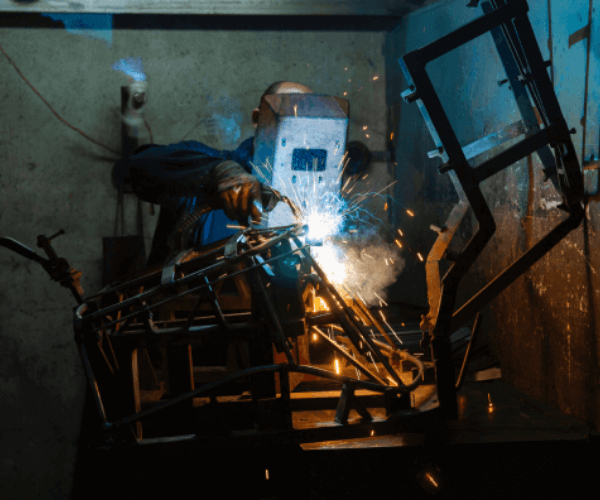

The manufacturing process takes a long process to make a superior quality mould.

While manufacturing the moulds and machines we make sure that no detail is left inattentive. The attention to detail makes it possible to create high-quality moulds and machines for our customers.

Complex geometric parts with stringent dimensions are produced by milling the steel which is later carried out by welding the parts.

Piyush Rotomac is conveniently located in one of the largest Industrial Area in India. Every day although, we ship finished products all around the globe: this ranges from doing weekly deliveries of products to North & South America, Asia and Europe.

Another of the many reasons clients have stuck with us for decades is because we don’t nickel and dime them for things like the storage and maintenance of moulds. In fact, we’ve built our entire facility around ensuring we can continue doing for our clients.